Why the receptacle part slips after installation?

I have the following question:

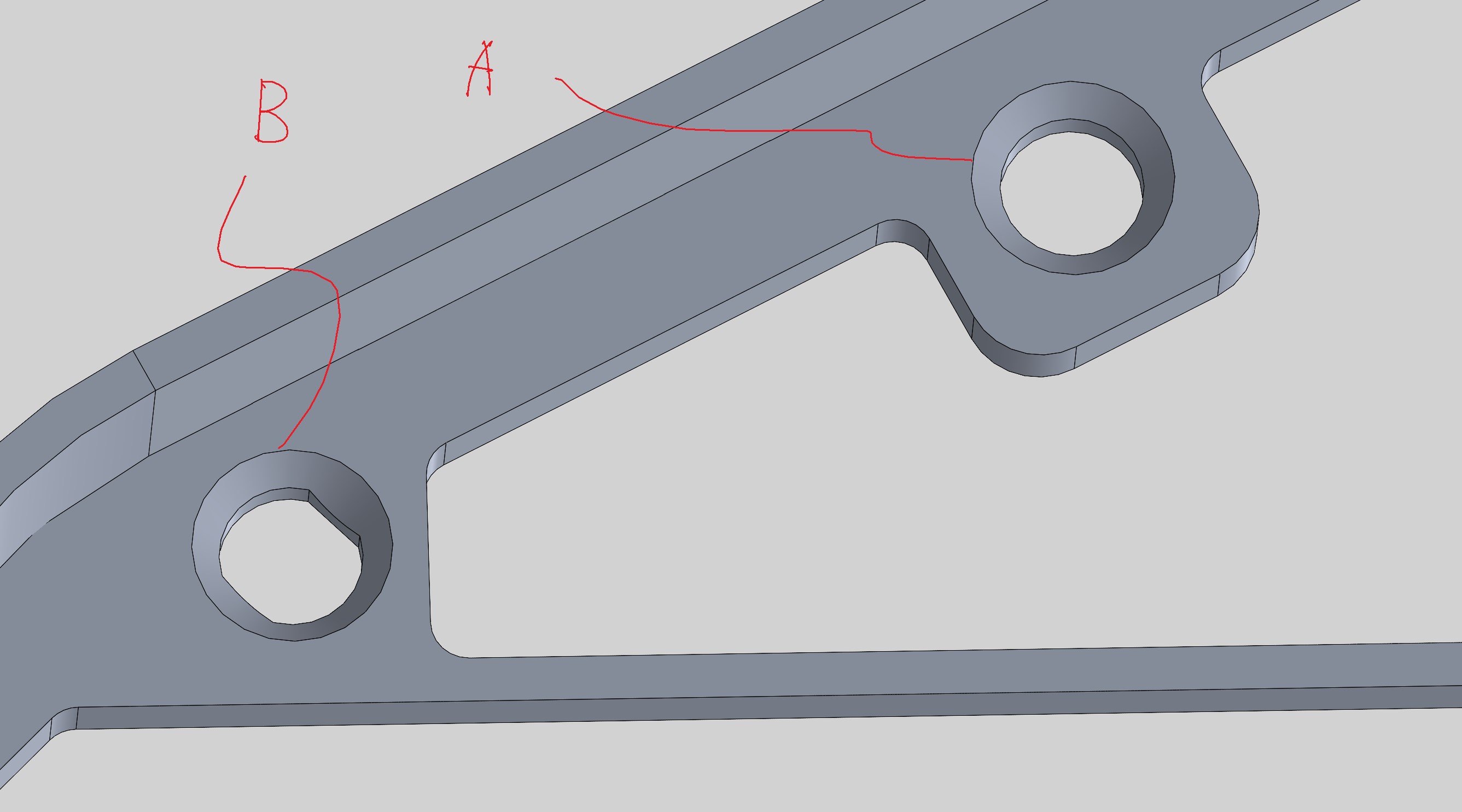

Do you use round holes (A) or holes with flat sides (B) to securely lock the female part (example MTHRTZZ)

Why I ask:

1. At the moment we used round holes (A)

a. Unfortunately, the female part rotates with the male part when closing the lock.

2. It is expensive to make holes with the flat sides in combination with a countersunk side.

My engineering hart tell me there is something we do know about your system and that round holes (A) should work.

Use case:

• In a 3mm aluminum plate with countersunk according to spec.

• Retaining nut tightened with required torque and locking compound.

Solution:

We have one of these receptacles on the Demobox and I trying to simulate the problem you report but I am not able to do so.

Maybe the stud is too short? Maybe you should glue in the receptacle?

Currently this is the only advise I can give.