Will the Turnlock parts be an exact fit into the existing holes we have allowed in our metalwork?

Question:

We need however to confirm a few things as if we are changing the manufacturer of items we have to get approvals from the end user, for this particular application.

Firstly will the parts be an exact fit into the existing holes we have allowed in our metalwork for the original Parts.

Can you also provide spec sheets or drawings so we can identify any physical differences in appearance to the end user.

Finally we need to have good confidence that the parts have equivalent strength in operation, have you any test data/certificates?

Answer:

They will be an exact fit as they are identical.

We have successfully changed over a customer in Malaysia back in 2012, and they kept on ordering these until 2016, (probably was for a contract for Boeing)

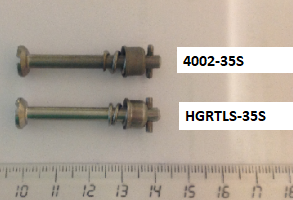

As you see there is a slight difference in color as the composition of the metal of 4002-35S as that one is made in the USA, however the stainless steel we have is also fully compliant, parts are also stamped, which makes them identical in strength.

For that customer we did a comparison and made a statement:

4002-31S and HGRTLS-31S are equal in form, fit and function ; guaranteed tensile strength and corrosion resistance are alike.

As for the ring, if you had good experience, please use the HGRGRZ, which is steel zinc plated.

As a consequence:

Parts will be an exact fit into the existing holes.

Spec sheet, we do not have, but above you see the appearance differences.

There is no test data available as customers are always responsible to test products within their own application.

However, the data that is mentioned in the catalog is valid.